Solid-liquid calculations (SLE) are of equal importance as that the liquid-vapor calculations (VLE) are, since during the production of polymers solid polymer is the end product and is often not desired to occur during the process in order to prevent clogging of the equipment.

When performing SLE calculations the thermodynamic model is not the same for the different phases. Liquid and vapor phases are modeled by using an equation of state (EOS) and the solid phase is modeled by using a separate model that can only be used for solid phases.

The approach taken in VLXE is taken from three articles given in the references below.

Two different versions of the same model is implemented:

•Original Pan & Radosz

•Full Pan & Radosz

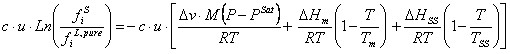

Original Pan & Radosz:

The heat capacity terms are dropped and the volume for both solid and liquid is assumed to be constant

Where:

![]()

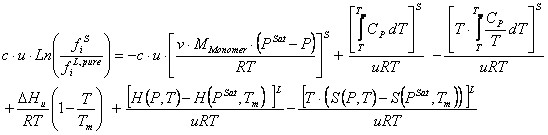

Full Pan & Radosz:

The heat capacity terms are keep intact and the liquid phase is modeled by using the selected equation of state:

where:

![]()

User input:

Parameter |

Description |

Value of polyethylene |

c |

Gives the fraction of the solid polymer i.e crystal |

Defined by the user |

|

Enthalpy of mixing per mole of crystal unit |

8220 J/mole |

|

Melting temperature for each pseudo component |

Defined by the user |

|

Density of amorphous polymer |

0.853 g/cm3 |

|

Density of crystalline polymer

|

1.004 g/cm3 |

|

Molar mass of monomer |

28.054 g/mole (Molar mass of ethylene) |

|

Solid->Solid transition temperature |

Defined by the user |

|

Enthalpy of Solid->Solid transition |

Defined by the user |

|

Heat capacity of solid polymer 4th order polynomial |

Defined by the user |

The possible SLE calculations are:

•Cloud temperature

•Cloud polymer mass fraction

•Flash at fixed temperature and pressure.

•Cloud temperature line at fixed pressure.

For more information see the references 17, 18, 19